AI Robotics: When Warehouse Robots Get a Grip

Have a look at a contemporary warehouse nowadays, and you will encounter Autonomous Mobile Robots (AMRs) moving silently across the floors. They’re efficient, sure. But have you ever seen anything when they cease? It is up to a human worker to do the laborious part, the picking and the placing. Such is the multi-billion dollar bottleneck. Now there is a new generation of AI Robotics crashing in, which does not only confer movement to robots, but also dexterity. Let’s explore this shift.

The Last Meter Problem: A Billion Dollar Bottleneck

AMRs brought a revolution in transport. They still do not complete the puzzle, though. The actual price is the touching labour. An employee still uses his legs to get to a place, pick up something and transfer it. This operation cost is more than half of the operational cost of a warehouse. It is also physically demanding causing high turnover. In simple words, it is only an increase in the speed of the shelves that will cause a larger traffic congestion at the pick point. We require a system that will accomplish the whole job.

We have automated the taxi, but we have a need of a valet to take the package out of the trunk.

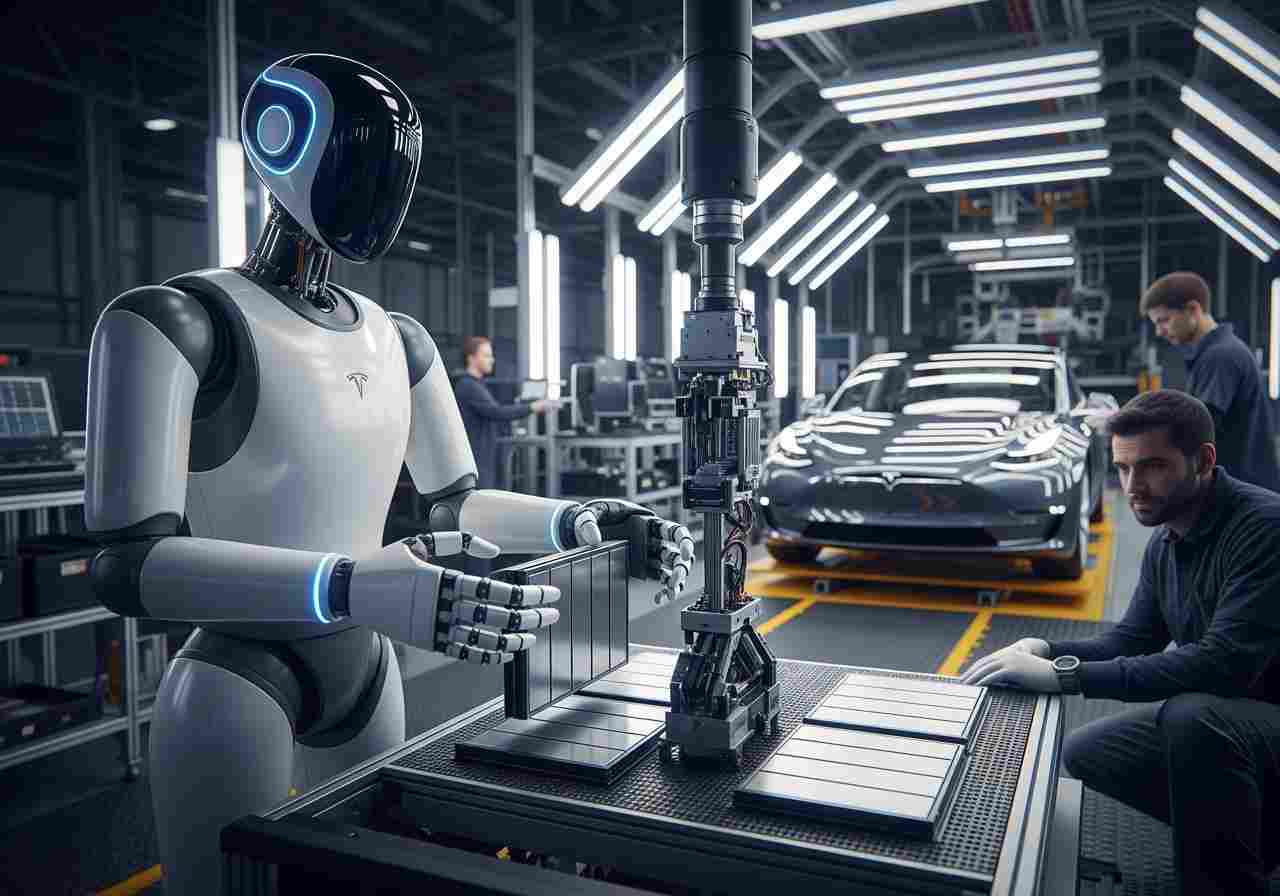

Get to Know the Mobile Manipulator: Brains and Brawn, Combined

So, what is the solution? Insert the mobile manipulator. Visualize an AMR which does not just carry a shelf. It instead possesses an advanced arm and an intelligent gripper. It is based on powerful vision AI to view a cluttered bin of items. Then it strategizes a path that its arm will follow to pick the right product. This isn’t science fiction. They are already being used by such companies as Boston Dynamics. This is a basic advancement in skill.

Key Components:

- High Vision Systems: These are not cameras of the cheap sort. They are multidimensional sensors which generate a three dimensional representation of a turbulent environment.

- Adaptive Grippers: Ranging between soft suction cups to two-finger claws, the end-effector is selected to do the job.

- Single brain AI: It is a system in which navigation intelligence and manipulation logic are integrated.

Stretch: A Case Study in Focus at Boston Dynamics

Let’s get specific. The viral Humanoid Robot videos owned by Boston Dynamics were a strategic move in business. They built Stretch. This robot is not supposed to do backflips. It is only a truck unloading process. Stretch is able to independently work with aviation boxes up to 50 lbs. It is tireless and moves thousands of cases within one shift. Why is this significant? It represents a shift in the market towards flashy prototypes to machines that work hard and make a profit. It is already being used by major retailers such as Gap Inc. in order to minimize the time of unloading and the physical activity of their staff.

The reason Why This Changes Everything in Logistics

The impact is profound. First, it develops actual end-to-end automation. This is where an order can be picked, packed, and sorted with a minimum human involvement. Second, it enhances the safety of workers significantly. Robots replace the awkward and monotonous distance lifting. This minimizes injuries at the work place. Lastly, it places a new role in humanity, that of robot supervisor and exception handler. The employees are able to reskill, working on the complex issues that machines are not able to address.

It is not about the replacement of people. It’s about augmenting them. We are eliminating the tediousness, rather than the honor, of labor.

The Technology Behind the Touch: It is All about the AI

It is not just the magic of the metal. It’s in the software. The machine intelligence of these systems is extremely complicated. It has to do real-time motion planning in order to prevent collisions. It must also be able to identify thousands of objects. Moreover, it is a learner of each pick. This machine learning cycle implies that the system becomes more intelligent and is accelerated over time. This is a perpetual change of the game when it comes to the effectiveness of operations.

Obstacles to the Adoption Process

Naturally, the road does not run smooth. The initial capital is huge. The technical challenge of integrating these complex robots with the old warehouse management systems is a complex task. In addition, it is still challenging to deal with an infinite range of SKUs, such as flexible clothes and rigid electronics. There is no gripper that suits all things. As a result, hybrid workflows will be initiated in many facilities. The close relationship between humans and robots is going to continue.

An Introductory Opinion on the Spot

I have experienced the exhaustion of the eyes of managers as a supply chain consultant. They are instructed to work harder with lesser, quarter after quarter. I recently visited the location where a Stretch robot was being tested. The most outspoken opponent was an old-time floor manager. One week later he informed me, I thought it would break. Now, I see it’s just a tool. And it allows my team to do work the one that involves the use of their brains. And the fact that that perception of threat has changed into a tool, is all.

The Future: Beyond the Box

What comes next? We will witness armies of such robots conversing. They will create a mesh network of cooperation in the warehouse. Others are going to guess at general-purpose Humanoid Robot employees. But machines made specifically to do it are solving the current challenges, with brutal efficiency, such as Stretch. The AI Robotics of the future in the logistics business is not creating a mechanical human. It is all about creating the right tool to the task.

Final Thought:

It has ceased to be a debate on whether to automate or not. It is concerned with the extent of automation. Companies that stand by easy transport robots are only cow-path panners. It will be the ones who adopt systems that see, think and act that will enjoy the real competitive advantage. The warehouse of tomorrow is not going to be moving only. It will be working.